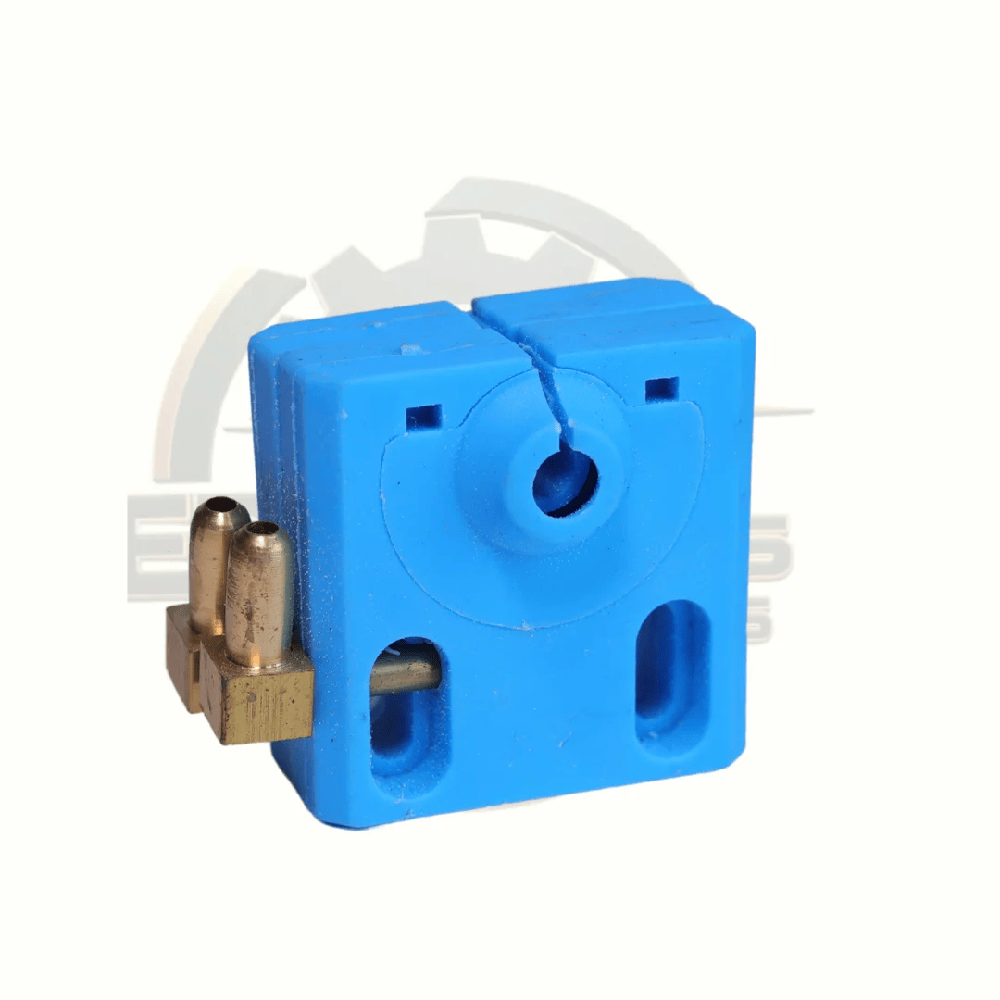

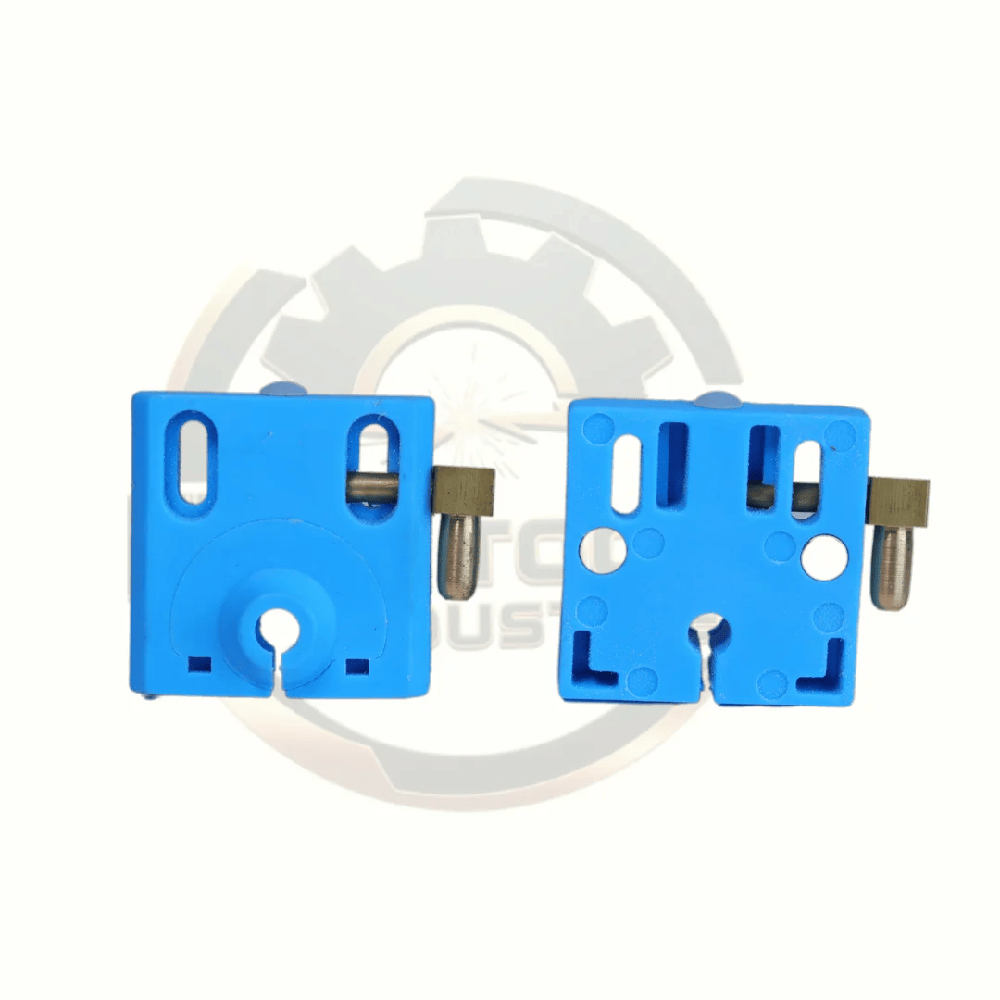

EDM Water Nozzle Plate

Price 598.0 INR/ Piece

EDM Water Nozzle Plate Specification

- Pressure

- 6 Bar

- Surface Treatment

- Polished

- Pattern Dimensions

- As per EDM Standard

- Diameter

- 25 Millimeter (mm)

- Capacity

- 15 Pcs/min

- Air Consumption

- Not Applicable

- Air Inlet

- 0.00635 Meter (m)

- Thread size

- 1 Inch

- Operating Pressure

- 4 Bar

- Product Type

- Thread Type

- Material

- Copper

- Metals Type

- Copper

- Plastic Type

- PTFE

- Usage

- Industrial

- Size

- Standard

- Weight

- 200 Grams (g)

EDM Water Nozzle Plate Trade Information

- Minimum Order Quantity

- 20 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 2 Days

- Main Export Market(s)

- Asia, Middle East

About EDM Water Nozzle Plate

EDM Water Nozzle Plate is a precision-engineered component used in Wire Cut EDM machines to control and direct the flow of dielectric water during the cutting process. It ensures uniform flushing around the cutting zone, helping to remove debris and maintain stable sparking conditions for accurate and efficient machining.

Manufactured from high-quality wear-resistant material, the EDM Water Nozzle Plate offers excellent durability, dimensional accuracy, and long service life. Its precise hole alignment and smooth finish provide consistent water pressure, reduce wire vibration, and improve cutting accuracy and surface finish.

This nozzle plate is compatible with most Wire Cut EDM machine models and is widely used in tool rooms, die & mold industries, and precision engineering applications.

Key Features:

Ensures uniform dielectric water flow

Improves cutting stability and accuracy

Reduces wire vibration and breakage

Precision-machined holes for effective flushing

High wear resistance and durability

Easy installation and replacement

Suitable for continuous EDM operations

Advantages:

Enhances flushing efficiency

Improves surface finish and cutting speed

Reduces machine downtime

Extends wire and machine component life

Frequently Asked Questions (FAQs)

Q1. What is the function of an EDM Water Nozzle Plate?

It directs and controls dielectric water flow to the cutting area, ensuring proper flushing and stable EDM performance.

Q2. Is this nozzle plate compatible with all Wire Cut EDM machines?

Yes, it is compatible with most standard Wire Cut EDM machines. Custom designs can be provided if required.

Q3. How does a nozzle plate improve cutting quality?

Proper water flow removes debris efficiently, reduces wire vibration, and maintains consistent sparking, resulting in better accuracy and surface finish.

Q4. Is this part suitable for continuous industrial use?

Yes, it is designed for continuous operation with high durability.

Q5. Can custom sizes or designs be supplied?

Yes, customization is available as per machine model and customer requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry